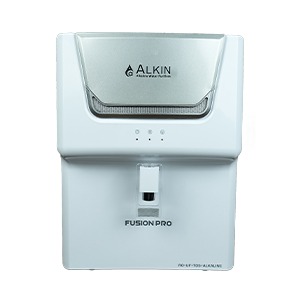

How Alkin Dispensers Reduce Plastic Waste, Cost and Logistics in Schools, Factories and Gyms

Providing safe drinking water at scale is not only a health requirement but also a major operational task. Schools must keep children hydrated during long days. Factories must serve large shift volumes under heat and physical load. Gyms must supply clean, fresh water to members before and after workouts. Many facilities still rely on packaged 20-litre jars or single-use plastic bottles, which are expensive, difficult to manage and environmentally harmful.

Alkin solves this through robust point-of-use dispensers and RO-based hydration stations designed for high footfall areas. By purifying water onsite and dispensing it safely, Alkin systems remove the need for disposable bottles and frequent jar deliveries. This article explains, in practical terms, how Alkin dispensers reduce plastic waste, cut total cost of hydration and simplify logistics across schools, factories and gyms. It also covers quality, compliance, placement strategy, maintenance and a simple method to estimate return on investment.

The Problem with Bottle-Dependent Hydration

1) Plastic Waste

Single-use bottles and even multi-use jar systems generate high plastic throughput. Empty bottles become waste; jars crack, need replacement and ship with plastic seals. Over a year, this creates large volumes of plastic that add to landfill and litter. The environmental burden also damages an institution's public image.

2) High Total Cost

Bottled solutions carry recurring costs:

- Purchase price of bottles or jars

- Transport, loading and storage

- Chilling equipment and electricity for stand-alone coolers

- Lost water due to spillage and wastage

- Losses from pilferage or miscount

- Staff time to check stock, call vendors, verify deliveries and handle empty returns

What appears affordable per unit often becomes costly once you add handling, storage and wastage.

3) Complex Logistics

Deliveries must be scheduled and checked. Jars are heavy and difficult to move across floors. Storage rooms are needed and must be kept clean. During peak demand or vendor delays, water can run short at the worst time.

4) Hygiene Risks

Open bottle necks, shared nozzles, dusty storerooms and mishandling of jars can compromise water quality. Consistency suffers when many third-party touchpoints are involved.

The Alkin Approach: Purify and Dispense at the Point of Use

Alkin dispensers are built around a simple principle: treat the incoming water at your location and dispense it fresh. Depending on your source and requirement, configurations can include RO, UV, UF and alkaline mineralisation. With proper pre-filtration and scheduled service, Alkin dispensers deliver clear, safe water throughout the day without relying on external bottle logistics.

Core Advantages

- Eliminates bottle inflow: No 20-litre jars, no single-use bottles

- Cuts recurring cost: Pay for filtration media and predictable service instead of endless bottle deliveries

- Simplifies operations: No storage, counting or returns; one system, one service schedule

- Improves hygiene: Closed purification path, stainless or food-grade wet parts, controlled dispensing

- Enhances taste and compliance: TDS control and optional alkaline for smooth mouthfeel; documentation for audits

How Alkin Dispensers Reduce Plastic Waste

Onsite Purification Ends Bottle Dependency

When a dispenser purifies mains or borewell water onsite, you no longer need packaged units. This removes thousands of bottles or jars per year for a medium-sized site. Students, workers and members refill their reusable flasks or paper cups.

Durable Hardware and Long-Life Filters

Alkin designs for commercial throughput, with long-life RO membranes and robust pre-filters sized to the actual load. Fewer replacements mean less plastic in the form of spent cartridges compared with consumer-grade devices that fail early in high-usage areas.

Refill Culture

Signage near Alkin stations promotes refilling and normalises bottle-free hydration. Institutions can issue branded steel or BPA-free bottles. This reduces the flow of single-use plastic into canteens and vending machines.

How Alkin Dispensers Cut Cost

1) Shift from Variable to Predictable Spend

Bottles and jars are a variable cost that grows with headcount and weather. Alkin converts this into a predictable maintenance plan: scheduled filter changes, periodic service and moderate electricity for chilling or heating (if enabled).

2) Lower Handling and Storage

No stock counting, no storerooms packed with jars, no empty returns. Freeing space is a hidden saving, especially in schools and gyms where every square metre counts.

3) Less Waste and Pilferage

With direct dispensing, the opportunity for pilferage and spillage falls. You dispense only what is consumed, so you pay exactly for usage, not for lost inventory.

4) Energy Efficiency

Modern Alkin dispensers use efficient compressors for cooling and insulated tanks to reduce cycling. Compared with running multiple old coolers and storing cold jars, a right-sized station can reduce electricity cost per litre dispensed.

How Alkin Dispensers Simplify Logistics

- No daily vendor coordination: Service is planned monthly or quarterly instead of constant deliveries.

- Easy scaling: To serve more people, add a dispenser line or upgrade filter capacity, not a new vendor contract.

- Cleaner canteens and corridors: Without jars piling up, movement lanes remain safe and tidy.

- Auditable routines: You can document maintenance on a simple schedule for health and safety checks.

Technology Options for Different Water Sources

Alkin recommends matching the dispenser to your water source:

- Municipal water, low TDS (< 300 ppm): UV + UF dispensers; optional alkaline for taste

- Borewell or mixed source, moderate to high TDS (≥ 300 ppm): RO + UV + UF with TDS control; optional alkaline cartridge for smoother mouthfeel

- Taste or acidity concerns: Add alkaline mineralisation to RO for balanced pH and better hydration comfort

All commercial builds use food-grade piping, hygienic tanks and sealed UV chambers to keep water safe from the point of entry to the point of dispense.

Where Alkin Dispensers Deliver the Most Value

Schools and Colleges

- High footfall at short breaks requires fast dispensing and multiple taps

- Easy refill culture reduces canteen plastic and litter

- Hygiene and maintenance logs support inspections and parental trust

- Cooling function supports hot climates and afternoon sessions

Placement tips: One station per floor near stairwells, plus one outside the canteen and near the playground. Provide bottle-filling height taps for younger students.

Factories and Warehouses

- Shift hydration demands large volumes at bell times

- Workers appreciate cool water near lines and docks

- Industrial dust makes closed purification and stainless or powder-coated bodies important

- Reuse RO reject water for cleaning floors or gardens where appropriate

Placement tips: Stations at entry gates, near time-clock areas and close to long production lines. Provide splash-proof floors and clearly marked reject-water reuse points.

Gyms and Fitness Centres

- Members require quick refills pre- and post-workout

- Alkaline RO is popular for smoother taste and perceived hydration comfort

- A refill station near the free-weights area reduces single-use bottle sales and litter

Placement tips: One dispenser at reception, one on the workout floor. Consider a third near group class studios.

Example ROI Thought Process (Simple and Practical)

You can estimate savings with a simple approach:

- Current monthly bottle/jar cost

- Add storage, handling and wastage cost (staff time, space, losses)

- Compare to Alkin monthly operating cost = service plan + estimated electricity

- Savings = (1 + 2) − 3

Most institutions see a clear drop in monthly hydration spend after switching, with the added benefit of reduced plastic waste and better housekeeping. Even if the headline per-litre price seems similar, the hidden costs of bottles often make them more expensive overall.

Safety, Compliance and Quality with Alkin

- Multi-stage purification tuned to your source (RO/UV/UF/alkaline as needed)

- NSF-style component standards and food-grade wetted parts where applicable

- Sanitary design for easy wipe-down and low microbial harbourage

- Scheduled service with cartridge life planning and membrane checks

- Documented logs for audits and inspections in schools and factories

Practical Implementation Guide

- Site Survey: Alkin or your facility team checks inlet water TDS, pressure, space and drainage. The right model and filter stack are chosen.

- Capacity Planning: Estimate peak-hour demand. Pick storage volume and number of taps to avoid queues.

- Plumbing and Power: Provide a stable inlet, a drain for RO reject and a dedicated power outlet with proper earthing.

- Accessibility and Hygiene: Ensure bottle-filling height, anti-slip mats and splash zones. Add signage to promote refills.

- Service Schedule: Lock a preventive maintenance calendar. Replace pre-filters on time to protect RO membrane life.

- Communication: Inform staff, students and members about the switch, the environmental benefit and refill norms.

Alkin Product Directions for High-Footfall Sites

While Alkin offers a range of residential and commercial machines, the following directions apply when configuring dispensers for institutions:

- RO + UV + UF + Alkaline for mixed or high-TDS sites needing smooth taste and wide protection

- Chilled/Normal/Hot dispense options for canteens and tea points

- High-capacity storage and multi-tap manifolds for peak periods

- Robust housings (powder-coated or stainless) for factory and outdoor corridor use

- Inline TDS control to standardise taste across seasons

Your Alkin representative can size the membrane, pre-filters and pumps to match your flow and recovery expectations.

Environmental Impact Summary

Switching from bottles to Alkin dispensers achieves:

- Drastic reduction in single-use plastic across the campus or plant

- Lower transport emissions by cutting daily jar deliveries

- Cleaner grounds with less litter and fewer damaged bottles

- Culture change: students, staff and members carry refillable bottles by default

These outcomes reinforce sustainability goals and make a strong statement during audits and community outreach.

Frequently Asked Questions

Why Choose Alkin

Alkin focuses on water quality for Indian conditions. The company builds systems that balance purity, taste, durability and cost of ownership. For institutions, Alkin offers:

- Engineering support for sizing and layout

- Predictable service plans

- Components chosen for long life under heavy use

- Options for RO, UV, UF and alkaline to match your source water

- Clean, simple user interfaces for quick refills

Institutions that adopt Alkin typically report lower monthly hydration costs, cleaner premises and positive feedback from users who value fresh, great-tasting water.

Conclusion

Relying on bottles or jars for hydration is expensive, messy and wasteful. Alkin dispensers provide a better model: purify onsite, dispense on demand and remove plastic from the workflow. Schools gain safer corridors and predictable costs. Factories gain faster refills and fewer delivery interruptions. Gyms gain a cleaner floor and happier members who can refill their own bottles with fresh, smooth water.

When you plan the switch, carry out a site survey, match purification to source water, size capacity for peak loads and lock a preventive maintenance schedule. With these steps, Alkin helps you cut plastic waste, reduce cost, simplify logistics and raise the overall standard of hydration at your facility.

To discuss an implementation plan for your campus, plant or fitness chain, visit https://alkinwater.co.in and request a consultation. Alkin will size the right dispenser stack, propose an installation layout and provide a clear service schedule so you can move away from plastic-heavy hydration for good.

Ready to Reduce Plastic Waste?

Contact Alkin today to discuss commercial water dispensers for your institution.

Request Consultation